Constructors are often faced with the challenge of deciding what cutting instruments are most suitable for certain purposes and what cutting benefits these instruments hold. More specifically, many construction engineers and workmen alike are not sure why the Wire Saw stands out in the construction industry. If you have ever felt like this, you’re in good company! In this article, we will briefly explain the salient functions and benefits of the concrete wire saw and why you should opt for them.

What is a Concrete Wire Saw?

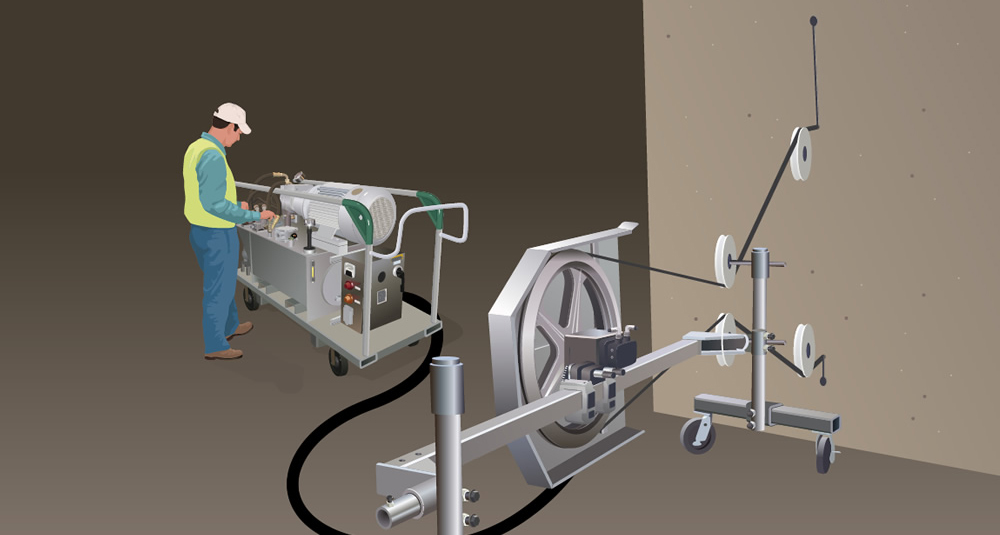

Concrete wire saws are handheld devices made from diamond-infused metal wires which are abrasive enough to cut through several materials such as concrete, steel and a few other materials. Wire saws are suitable for use where bulky cutting instruments cannot access, such as corners, underneath bridges, etc and are capable of removing substantial substance at a time requiring only water and/or hydraulic oil for lubrication when necessary.

Benefits of Concrete Wire Saws

1.Concrete wires saws save time by providing deep cuts

Now, here is how it works; the wires are made from materials with the ability to efficiently chop off large chunks of concrete, steel or whatever materials you are working on by providing you with deep range cutting. As this happens, more job is done and less time is used. You really don’t want to spend the whole day on sawing, do you? Concrete wire saw give you that advantage!

2.Concrete Wire Saws give you precise cutting

Wire saws operate with metal wires that are not only strong but also flexible. The wires are attached to the device drill holes and they sear through the cross section of the materials thereby cutting neatly according to specification. Concrete wire saws can therefore be used on old concrete and corners without fear of leaving tears and fractions on the concrete.

3.Concrete wire saws are neat to use

If there’s one excellent unique thing about concrete wire saws, it is the fact that they leave you with less mess to clean up at end of the day. This is because they produce less dust than other cutting techniques. The wires are designed to cut neatly into the surface of the concretetheteby producing very little dust in the process. Of course, you can make cleaning even easier by constantly lubricating with water, because the more lubrication, the less the dust and the less cleaning you have to do after cutting!

4.Concrete wire saws can be used anywhere!

Yes, literally anywhere! The machine is handheld, portable and electrically operated. This means you don’t have to worry whether you can use them at house corners, underneath bridges, on pavements, on beams, etc. It doesn’t matter whether the area you want to work on is indoors or outdoors, well spaced or tight, concrete wire saws are just readily available for use anywhere!

5.Concrete Wire Saws Cause Less Noise

Now, this feature is very important especially for construction workers who have to use the cutting equipment for a prolonged use of time. Unlike other cutting instruments that are likely to expose the user to temporary hearing loss which may grow into a permanent hearing damage, concrete wire saws produce very controlled sound during operation with minimal noise. This implies that you don’t have to worry about raising the entire neighborhood from bed if you choose to work in the morning or disturbing their sleep if you have to work late into the night.

Interestingly, the concrete grinding wheels and saws give you all round benefits. Apart from efficiency of work, speed and flexibility, and less noise, it also involves less risks. What more?