As far as recent leaps in technological advancements go, the 3D printer has taken over the mass manufacturing industry and put it into the hands of artisans in the cottage industry. Through compositing layers one at a time to create unique objects and components, it offers many advantages to the usual manufacturing processes. It reduces the period that it takes to produce a product while doing away the associated constraints making it a fun home activity. You can sell your unused cartridges and ink through sell toner cartridges for cash near me.

3D printing has a variety of applications that deliver a rapid design with higher levels of accuracy and the use of practical materials. Understanding these advantages allows designers to make informed decisions that optimize production thereby reducing cost. You can find some ways 3D printing is applicable at highly popular website Trust Advisor, and here are some advantages to using it.

Reduced Costs

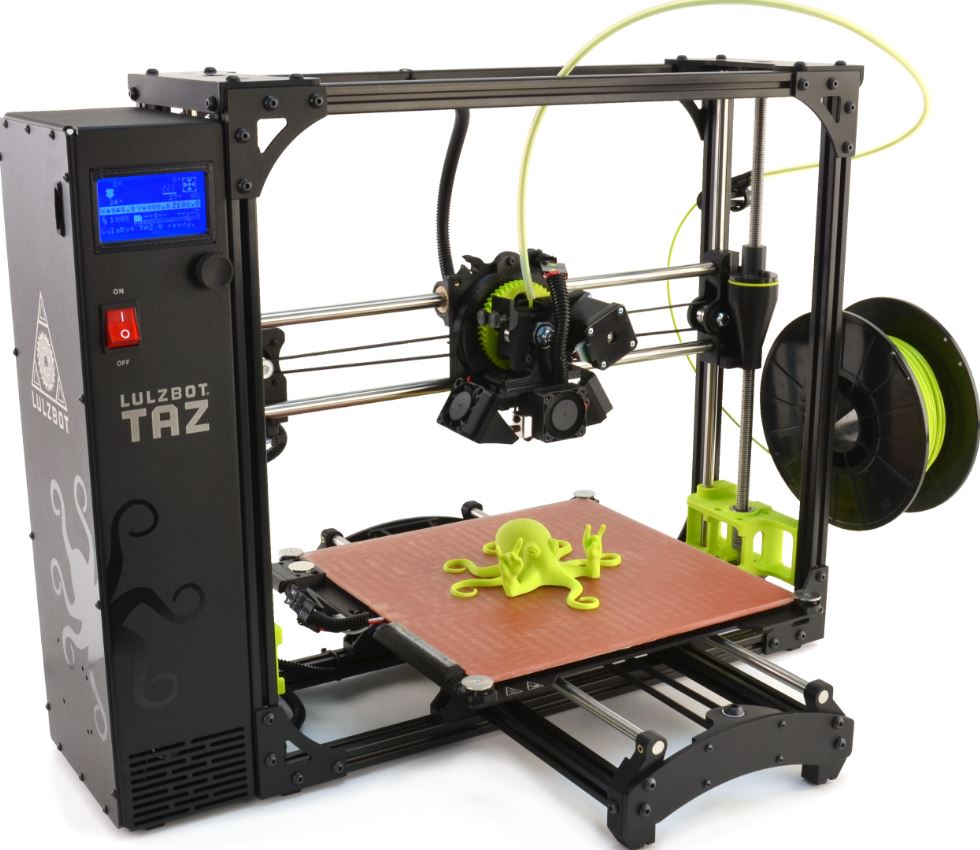

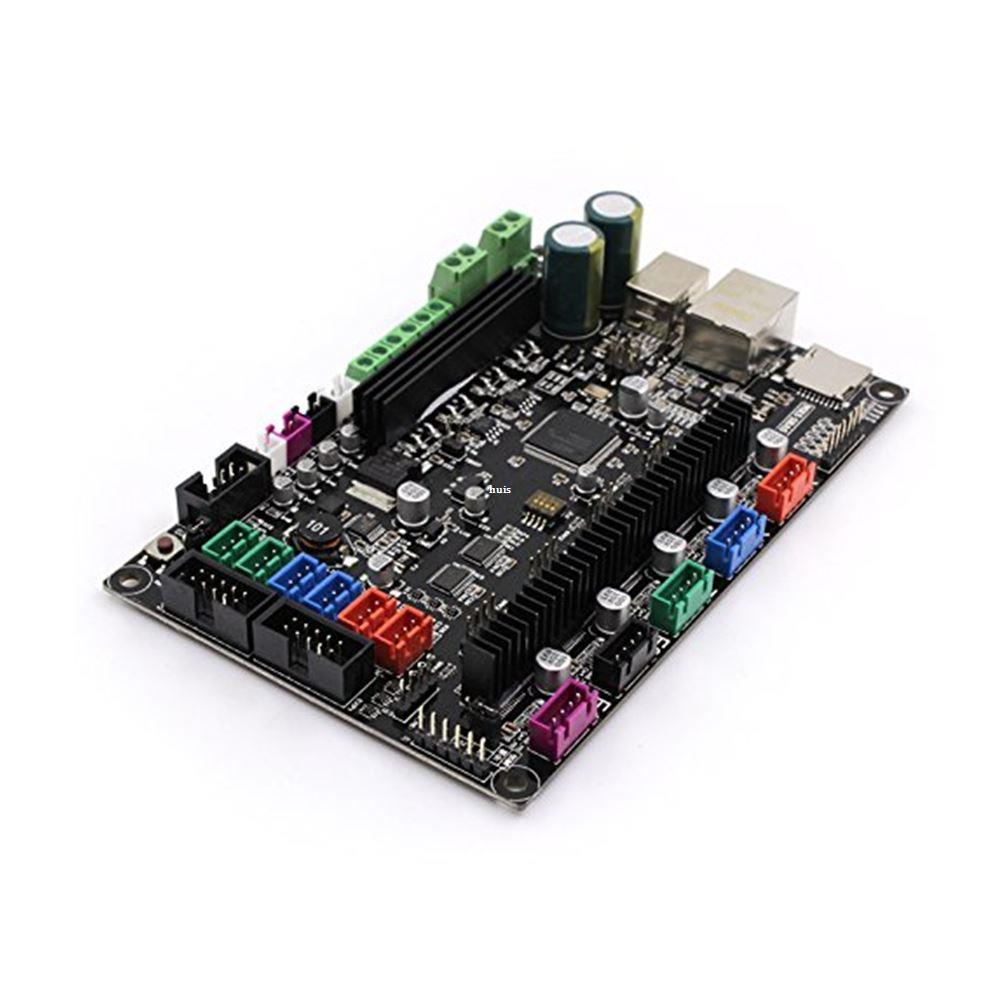

Machine costs: traditional manufacturing technologies consume so much electricity in the production of just one part. A majority of 3D, printers only require the same amount of power that a laptop needs.

Material costs: currently the price of materials is relatively high, but as the range of materials available increases, we expect that their cost will reduce overtime. However, when compared to traditional manufacturing processes the overhead is lower.

Labor costs: there is no need to hire skilled machinists or many people to operate many machines in a production line. All a 3D printer requires is a single operator to start the device so it can work on an automated process of creating parts from uploaded designs.

One-Step Manufacture

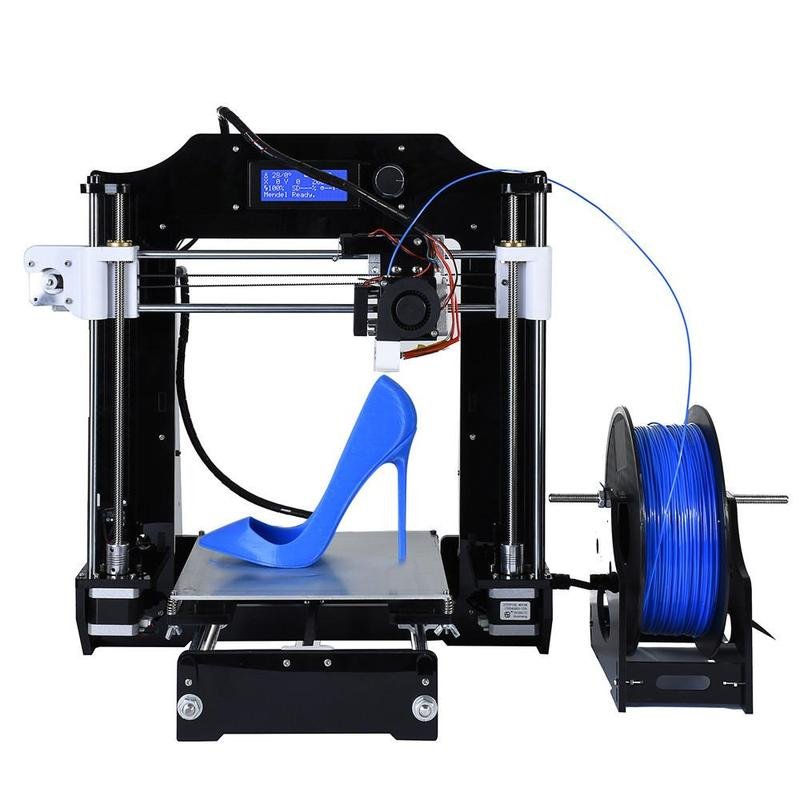

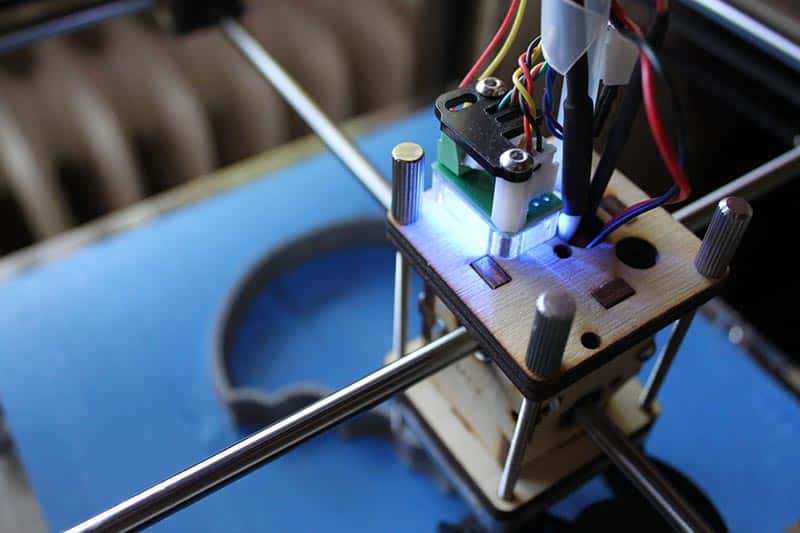

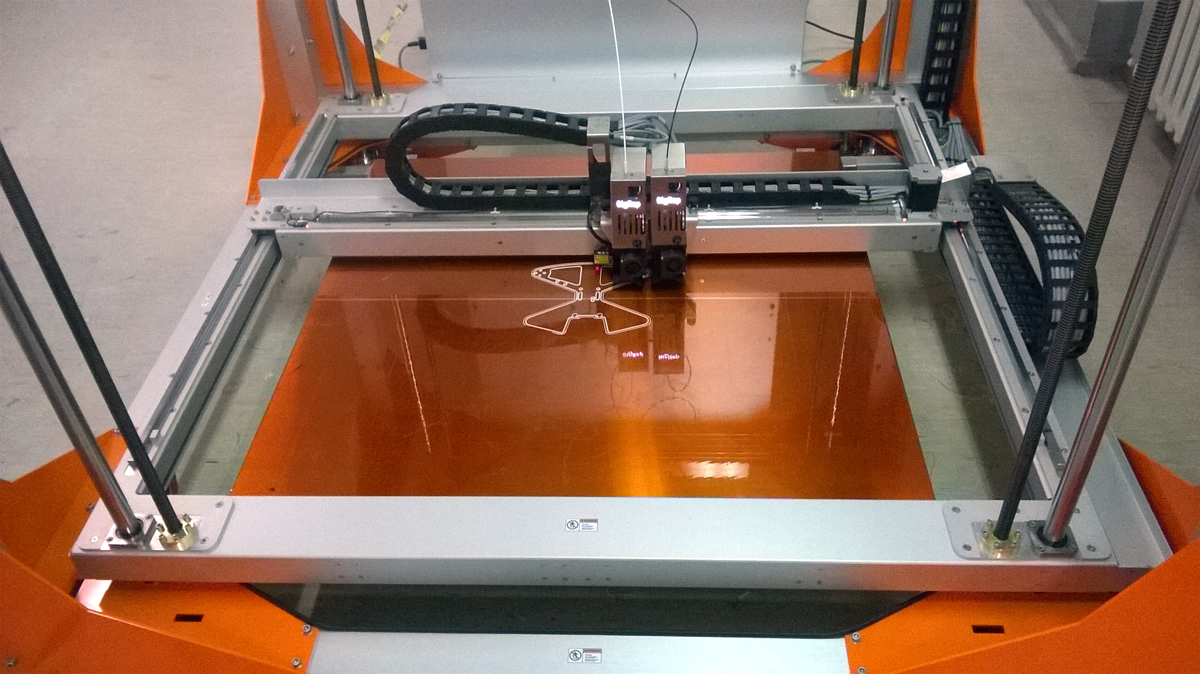

Efficiency is one of the most significant concerns for designers and manufacturers. Many components need to go through some steps of production in traditional manufacturing. However, with 3D printers, moving from a 3D model to a finished part is an intuitive and automated process. All the operator needs to do is upload the 3D model onto the 3D printer, and the machine does the rest. There are few if any errors because 3D modeling is an exact art, which churns out highly detailed models.

Rapid Prototyping

Prototypes are small models created to show what a complete product will look like and function. They come in handy for communicating ideas, anticipating future problems, and establishing the viability of a product before the commitment of more resources. After a working prototype gets approval, then the scale is increased to the actual size of a production model.

Traditionally, production of prototypes requires highly skilled artisans and craftsmen working under the designer, and it takes many deliberations and alterations. It used to take a lot of time and money to make prototypes. However, when 3D printing is involved, the designer can work on a design, upload it to a printer, and within hours have a working prototype to present.

Highly Customizable

Traditional mass-production industries depend on molds to cast parts, and this means that all the pieces come out looking similar. Therefore, there is no room for uniqueness. However, when using 3D printing, it is possible to alter a working prototype to fit different design and functionality needs.

An excellent example of an application of this aspect of 3D printing is how a dentist can modify teeth and things like dentures to suit the needs of different clients.

Easily Accessible

3D printers are becoming easier to access by the day. There are even 3D printing pens that produce the same results as 3D printers, but without the automatic movement that the printer offers, (the operator has to move the pen by hand). There are also many portable 3D printers in the market that can operate with little or no assembly. They can even work in a tough field like warzones and archeological digs.

Compatibility with Open-Source Platforms

Open-source technologies like Blender 3D software offer a robust mix of design tool and total creative freedom. The spirit behind such technologies is to liberate the masses from the firm grip of proprietary software. When you create a component with a proprietary tool, you require a license to have the right to use it. There are also limitations as to how you can modify the software. However, with open-source software, you are at liberty to alter the software as it would please you and whatever you produce is yours to do with as you wish.